Kyubi System © is a business unit of Comercial Arqué S.A specialized in RFID technology.

T (34) 932 615 300

Email: info@kyubisystem.com

Kyubi System ©

Carretera del Mig, 54. Hospitalet de Llobregat, BARCELONA

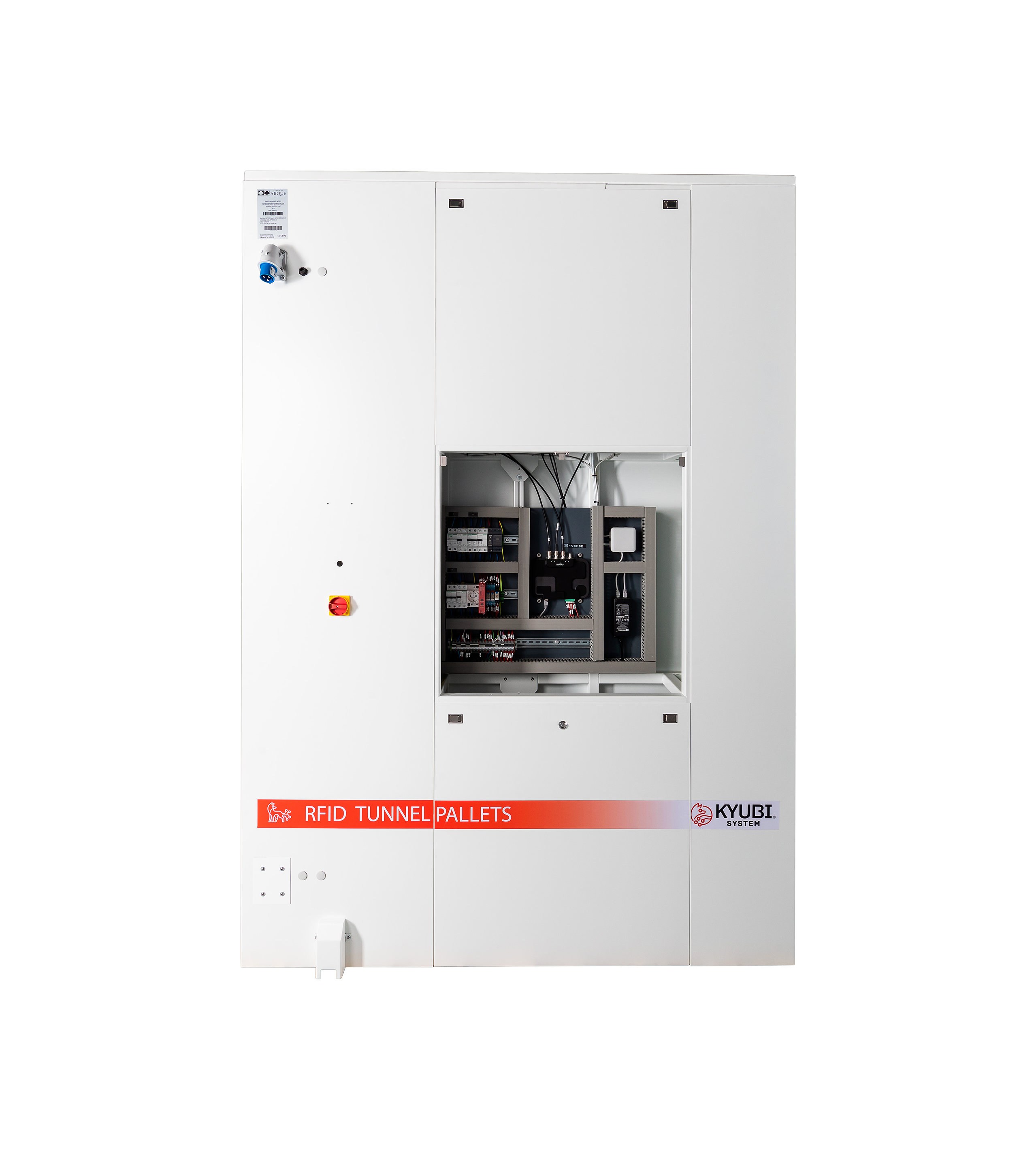

Transform your Logistics with RFID-AIR! Tunnel for Pallets

In the ever-changing landscape of logistics and supply chain management, staying ahead of the curve is key to success. Enter the revolutionary solution that is poised to transform the way you manage pallets and freight: RFID-AIR! Tunnel for Pallets.

Imagine a logistics system that offers unmatched accuracy, configurability and efficiency, all thanks to RFID technology. That's precisely what the RFID-AIR! Tunnel for Pallets offers, making it a must-have for companies looking to optimize their operations and improve their bottom line.

Innovative Mass-Read Technology

The cornerstone of the RFID-AIR! Tunnel for Pallets capabilities lies in its innovative mass scanning system, powered by advanced RFID technology. The result? Read rates that consistently exceed 98% in calibrated environments. Say goodbye to the frustration of inaccurate reads and welcome accuracy like never before.

Configurable to Your Needs

Whether you're dealing with pallets of different sizes or items of different weights, RFID-AIR! Tunnel for Pallets adapts effortlessly. Its pallet size is fully configurable, accommodating pallets weighing up to 2500 kg. No matter the load, this system can handle it.

Efficiency Redefined

Choose between reading a single tag on the pallet or opt for massive RFID reads of up to 2500+ items on a pallet, all with extreme accuracy. This level of flexibility allows you to tailor your processes to your unique needs, improving overall efficiency.

Tackle Challenging Readings with Ease

RFID tags causing headaches with your old management system? Not with RFID-AIR! Tunnel for Pallets. Its automatic jogging feature ensures that even the most difficult RFID reads are accurate, reducing bottlenecks and keeping operations running smoothly.

Seamless Integration

We integrate a high performance barcode reader at the infeed or opt for manual RFID reading to identify the incoming pallet. Through this reading we query the RP system for the items that go in each box and return the result ensuring a smooth workflow.

RFID-Brain: The Main Engine

Driving RFID-AIR! Tunnel for Pallets is the innovative RFID-Brain system. This robust platform handles read/write operations for RAIN RFID providing intelligence to our Tunnel.

Adaptable to any environment

Installation in demanding environments is simple. Our RFID-AIR! Tunnel for Pallets can be seamlessly integrated into your existing conveyor configuration, with a minimum distance requirement of only 1.5 meters between tunnels.

Embrace the Future of Logistics with RFID-AIR! Tunnel for Pallets

RFID- AIR! Tunnel for Pallets is not just an upgrade, it's a transformation. Say goodbye to inaccuracies, inefficiencies and costly disruptions in your logistics. Embrace the future of RFID-driven precision management and take your business to new levels of efficiency and profitability.

Ready to revolutionize your logistics with RFID technology?

Contact us today to find out how the RFID- AIR! Tunnel for Pallets can elevate your operations, reduce costs and ensure your business is at the forefront of RFID innovation.

Welcome to a new era of RFID-enabled logistics excellence!

TUNNEL

Designed to optimize logistic preocesses, high-end AIR! Tunnel device includes RFID tag devices that execute massive readings of items, packages and pallets with the highest precission rate of the market.

The AIR! Tunnel has been designed for Shipment Verification and Stock Management. Its “infinite opportunity” feature manages even the most hard-to-read badges through a smart process of alternate readings whilst syncing a smart back and forward movement of the package inside the tunnel.

Captured information is shown on the control screen, which is then can use to steer correctly their products. It is very productive in processes of goods receipt in warehouses, verification of exits to customers or recording of articles.

Air! Tunnel

Standalone version for quality processes

Or integrated in industrial lines for production processesHigh speed mode for reading / writing

For unattended production environmentsLogical integration through REST API

With internal data model for real-time decision making3 different working modes

Manual, semi-manual and automatic"Infinite opportunity" cycle for error handling

No need for additional return conveyor belts

RFID SPECIFICATIONS

- ETSI band 865–868 Mhz

- FCC band 902–928 Mhz

- Supported Tags EPCglobal Class 1G2, ISO 1800-6C, ISO 1800-6B, Ucode 1.19

- Transmission power +33 dBm / +36dBm

- RFID Regulations RoHS, ETSI EN 301 489, ETSI EN 302 208 y IEC 60950

- Optional Activation with external sensor

APPLICATIONS

- Cargo expedition

- Picking and packing control

- Warehouse inventory

- Dinamic Recording

LATEST POSTS

VIEW ALL - 04 June 2025 by KYUBI, in RFID technology

04 June 2025 by KYUBI, in RFID technologyKYUBI SYSTEM | RFID Solutions: Leadership in Traceability and Automation Strengthens with TRAKARI

KYUBI SYSTEM | RFID Solutions consolidates its leadership in intelligent traceab...READ MORE + 13 May 2025 by KYUBI, in RFID technology

13 May 2025 by KYUBI, in RFID technologyRFID: The Definitive Guide for Business Leaders in 2025 – Unparalleled Efficiency and Traceability with Kyubi System

For you, visionary leader: The future of asset, inventory, and supply chain mana...READ MORE + 30 April 2025 by KYUBI, in RFID technology

30 April 2025 by KYUBI, in RFID technologyRFID: What It Is, How It Works and Why It Is the Key Technology for Business Optimisation in 2025 and Beyond

In the dynamic landscape of digitisation and Industry 4.0, RFID (Radio Frequency...READ MORE +