Kyubi System © is a business unit of Comercial Arqué S.A specialized in RFID technology.

T (34) 932 615 300

Email: info@kyubisystem.com

Kyubi System ©

Carretera del Mig, 54. Hospitalet de Llobregat, BARCELONA

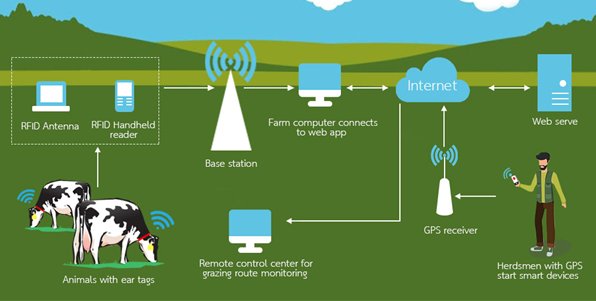

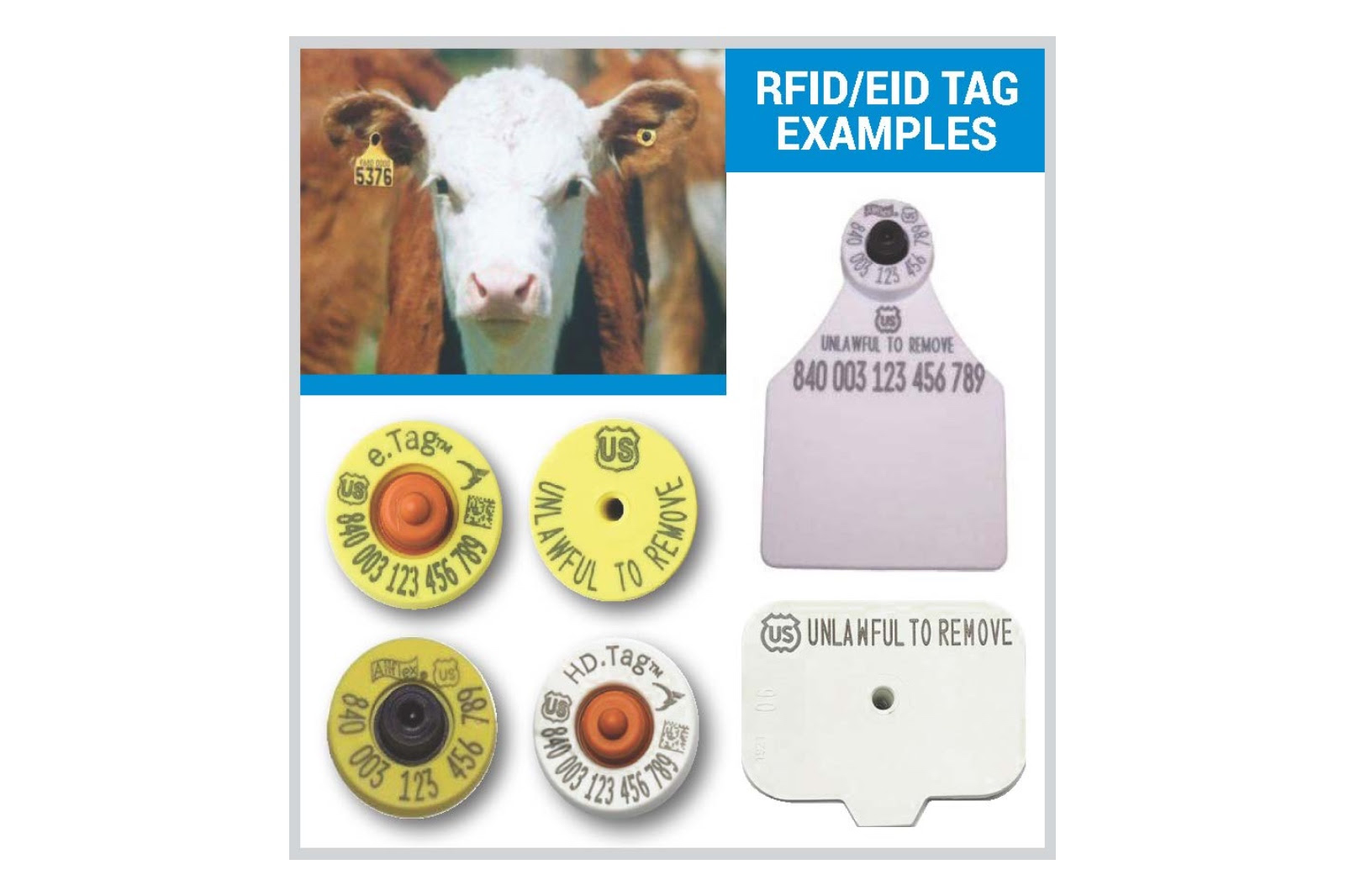

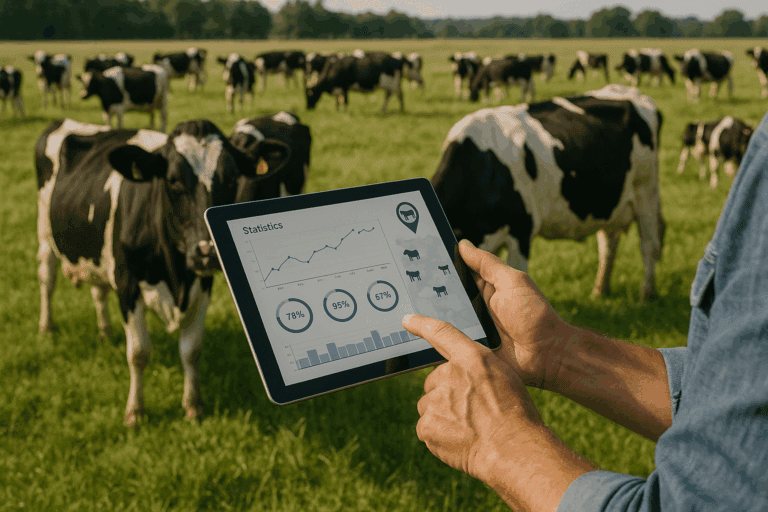

RFID in the meat sector

RFID technology facilitates the identification of all meat products, from the moment they enter the slaughterhouse until they reach the end consumer, ensuring accurate data collection through quick and easy identification.

RFID for beverages

The use of RFID technology in the beverage industry has contributed to greater efficiency in product management, as well as faster information gathering.

RFID for fruit and vegetables

From the field to the end consumer. RFID technology for fruit and vegetables in the agri-food sector offers security and accuracy in the process from harvest to the end consumer.