Kyubi System © is a business unit of Comercial Arqué S.A specialized in RFID technology.

T (34) 932 615 300

Email: info@kyubisystem.com

Kyubi System ©

Carretera del Mig, 54. Hospitalet de Llobregat, BARCELONA

The Importance of Traceability and Its Optimization with RFID

Traceability has become an essential element in modern industry. In an environment where efficiency, quality, and responsiveness are key factors, having systems that allow tracking each product from its origin to its final destination is a major competitive advantage. Traceability not only facilitates compliance with regulations and audits but also helps detect faults, optimize processes, and improve production and logistics planning.

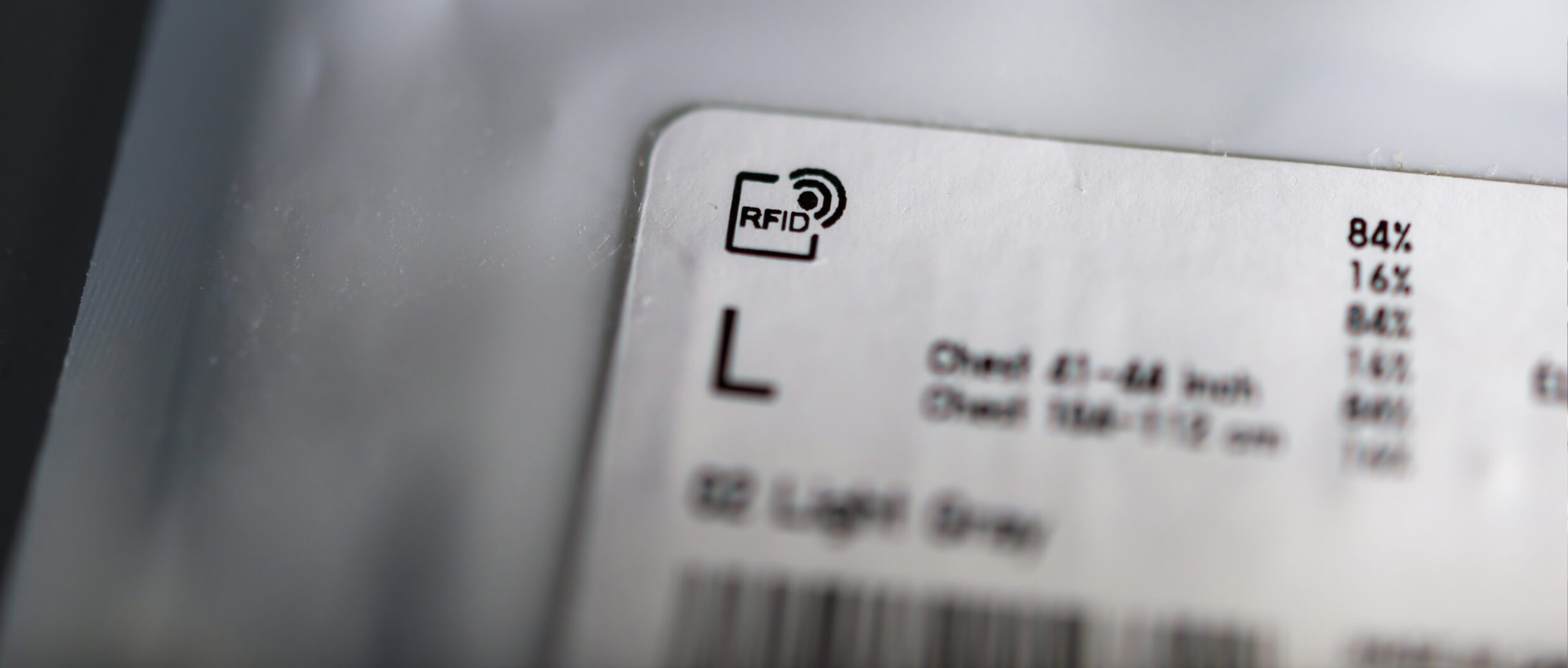

The incorporation of RFID technology (Radio Frequency Identification) has revolutionized industrial traceability management. Unlike traditional methods such as barcodes, RFID provides automatic, contactless, real-time identification of materials, products, or tools. This offers total visibility of the supply chain, reduces human errors, and streamlines information exchange between management systems such as ERP or MES.

Thanks to RFID, companies can monitor every stage of the production process, control inventory movements, know the exact location of assets, and respond quickly to incidents or deviations. This digital traceability enhances transparency, optimizes resource management, and supports more accurate decision-making based on up-to-date data.

Ultimately, RFID-supported traceability is not just a control tool but a cornerstone of industrial digital transformation. Its implementation boosts productivity, strengthens operational safety, and improves profitability, turning the supply chain into an intelligent, connected, and efficient system.

Sectors in the Industry with RFID