Kyubi System © is a business unit of Comercial Arqué S.A specialized in RFID technology.

T (34) 932 615 300

Email: info@kyubisystem.com

Kyubi System ©

Carretera del Mig, 54. Hospitalet de Llobregat, BARCELONA

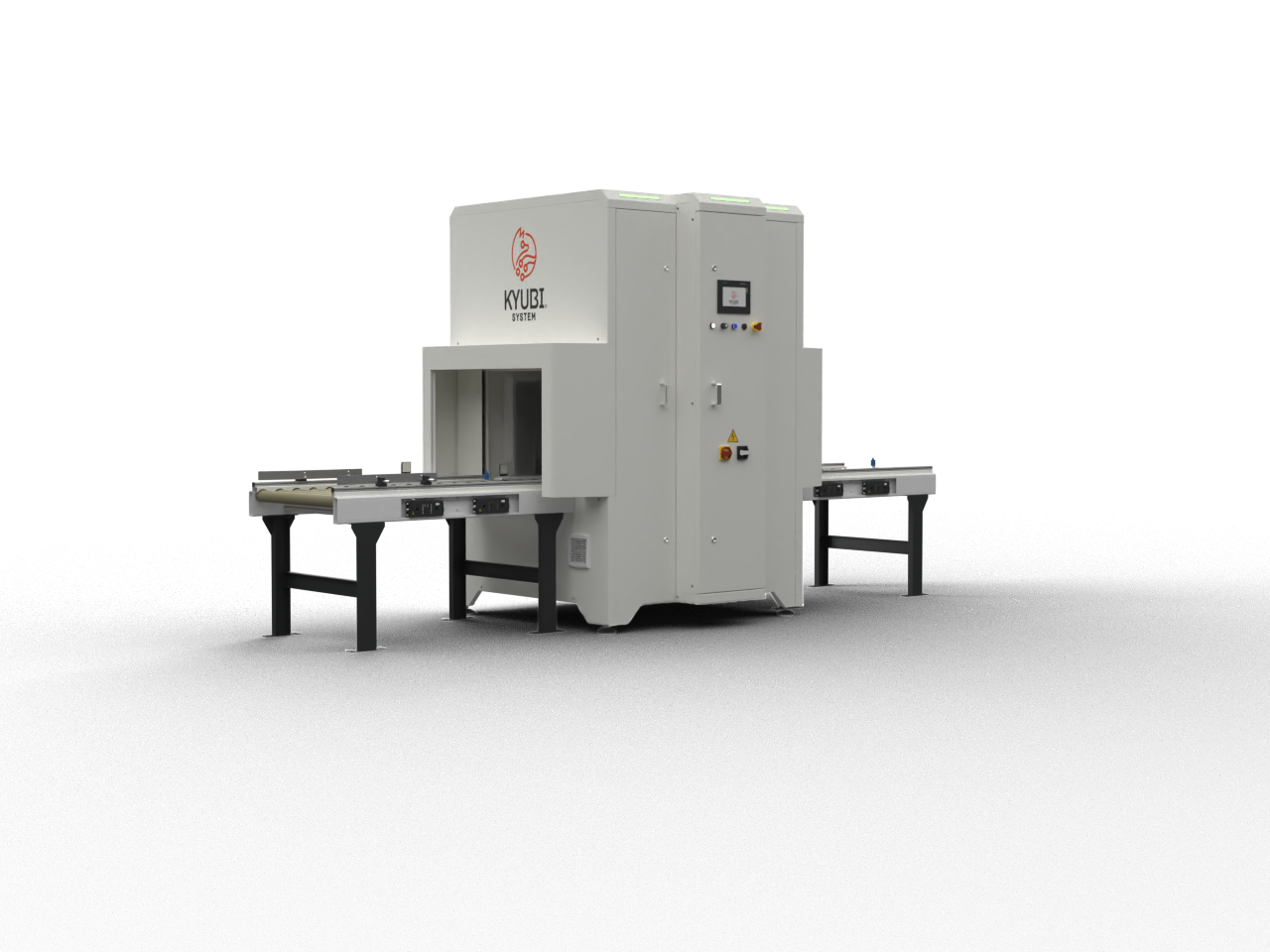

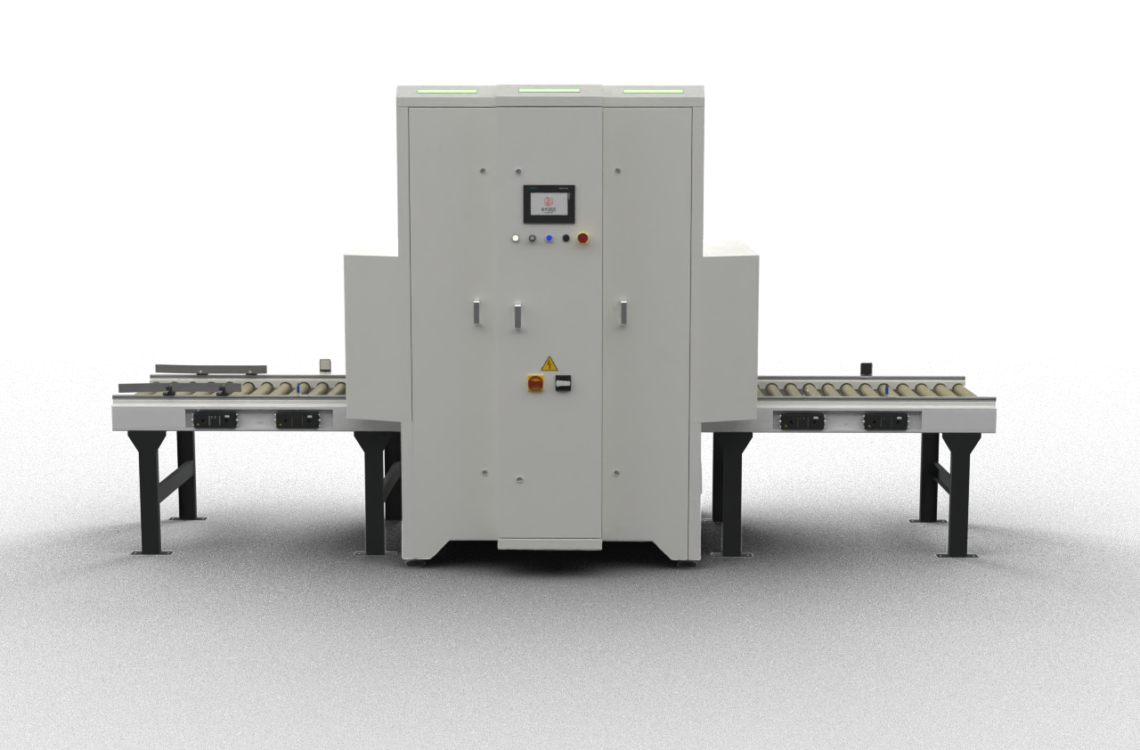

Industrial RAIN RFID tunnel for mass reading and process automation. The AIR! NOVO Tunnel is an industrial RAIN RFID tunnel designed for the automatic reading and writing of UHF RFID tags in unattended production and logistics environments. Its architecture enables the simultaneous identification of multiple items, ensuring high levels of accuracy, repeatability, and electromagnetic stability.

The AIR! NOVO Tunnel is intended for operations where processing speed, data reliability, and item-level traceability are critical.

Technical description of the AIR! NOVO Tunnel:

The AIR! NOVO Tunnel creates a controlled RFID reading zone, optimized for the mass identification of items in motion. The system enables content validation, logistics flow verification, and process automation without manual intervention or visual contact with the tags. Its closed design ensures a stable RF field, minimizing external interference and unwanted reads.

NOVO TÚNEL

Designed for industrial environments and high-volume operations, the AIR! NOVO Tunnel is a state-of-the-art UHF RAIN RFID tunnel built to automate the mass reading and writing of tags in unattended logistics and production processes. Its architecture creates a controlled reading zone that enables the simultaneous identification of multiple items with maximum accuracy, repeatability, and electromagnetic stability, even with goods in motion.

The AIR! NOVO Tunnel has been developed for tasks where data reliability and item-level traceability are critical: automatic goods verification, inbound and outbound control, shipment validation, and automated RFID inventory. Thanks to its enclosed design, the system minimizes external interference and reduces unwanted reads, ensuring consistent performance on continuous lines and demanding flows.

Captured information can be integrated directly into logistics and industrial management systems via Ethernet connectivity, enabling full automation of the RFID data flow. Robust and designed for continuous operation under industrial conditions, the AIR! NOVO Tunnel integrates into conveyor lines and accelerates decision-making, reducing operational errors and improving process quality control.

RFID technology in the AIR! NOVO Tunnel Supported standards

The AIR! NOVO Tunnel is compatible with the main UHF RFID standards:

- EPC Global Class 1 Gen2

- ISO 18000-6B

- ISO 18000-6C

- Ucode 1.19

Frequency bands

- ETSI EU1: 865–868 MHz

- ETSI EU2: 915–921 MHz

- FCC: 902–928 MHz

This compatibility allows the use of the AIR! NOVO Tunnel in international environments while complying with current regulations.

RFID reading performance

- Effective read distance: up to 120 cm

- Simultaneous reading of multiple RFID tags

- Reliable reading of items in motion

- High repeatability in continuous processes

- RF field optimization to minimize tag collisions

The AIR! NOVO Tunnel ensures stable behavior even in high-volume operations.

Communication and integration

- Connectivity: Ethernet 10/100 BaseT

- Visual status indicator via tri-color LED

- Direct integration with logistics and industrial management systems

The AIR! NOVO Tunnel integrates easily into existing IT architectures, enabling RFID data-flow automation.

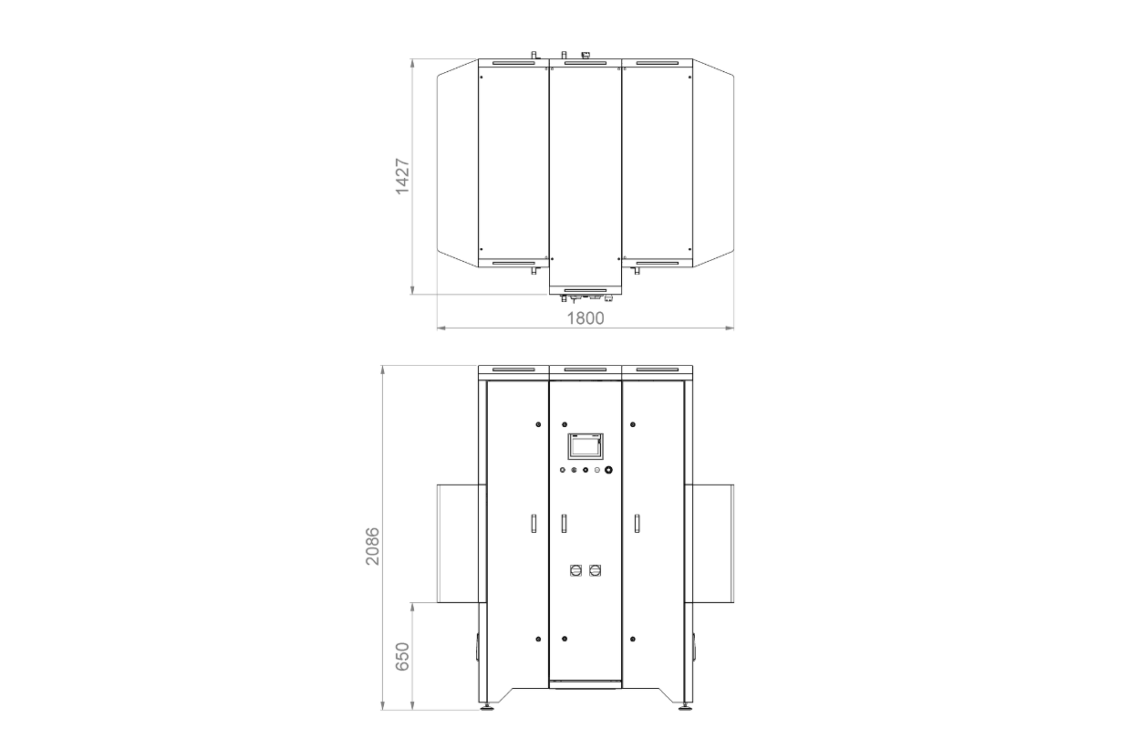

AIR! NOVO Tunnel dimensions

- Length: 1800 mm

- Width: 1501 mm

- Height: 2114 mm

Its design enables efficient integration into production and transport lines.

Electrical specifications

- Input voltage: 380–480 V three-phase

- Maximum power: 4 kW

- Input frequency: 50–60 Hz

- Internal voltage: 24 VDC

The AIR! NOVO Tunnel is designed for industrial environments with high energy requirements.

Environmental operating conditions

- Operating temperature: -20 °C to 50 °C

- Relative humidity: 5% to 96% non-condensing

These characteristics allow the AIR! NOVO Tunnel to operate reliably in warehouses, logistics centers, and industrial plants.

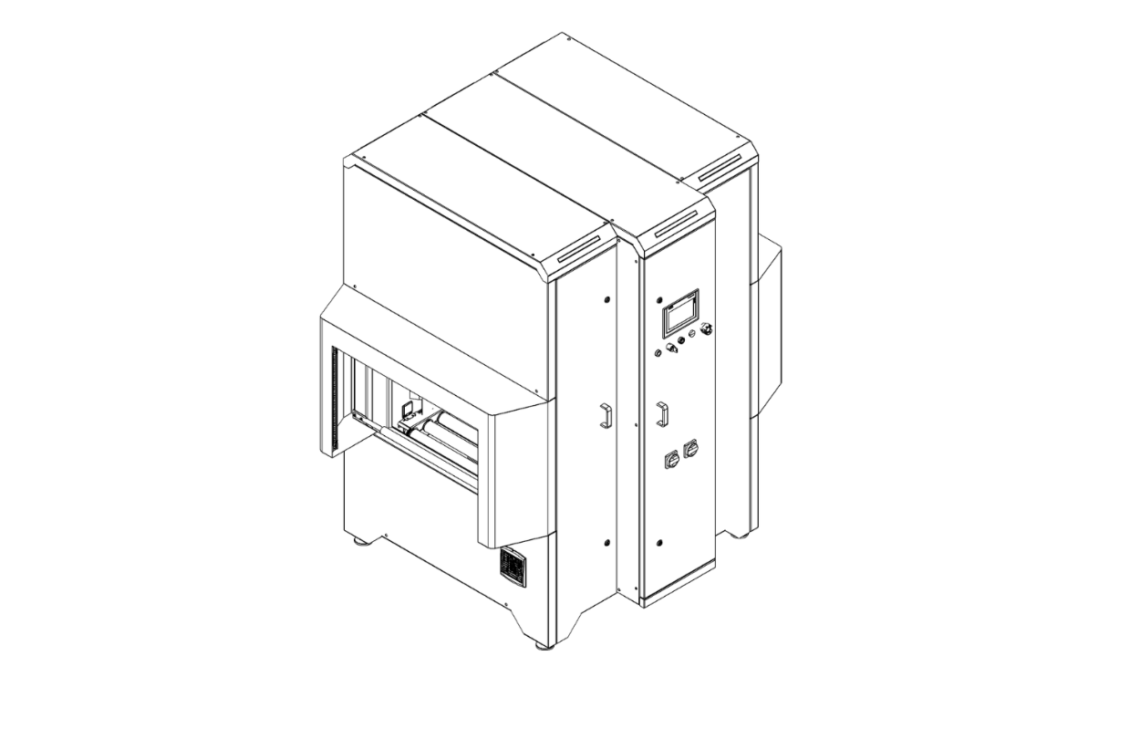

Industrial design and construction

The AIR! NOVO Tunnel has been developed for continuous operation in demanding environments:

- Aluminum, steel, and polycarbonate structure

- Robust design for industrial lines

- Approx. weight: 450 kg (depending on configuration)

- Direct integration into conveyor systems

AIR! NOVO Tunnel applications

The AIR! NOVO Tunnel is especially suitable for:

- Automatic goods verification

- Inbound and outbound control

- Automated RFID inventory

- Item-level traceability

- Unattended industrial processes

- Order and shipment validation

AIR! NOVO Tunnel technical benefits

- RFID reading without line of sight

- Mass and simultaneous identification

- Reduction of operational errors

- Full process automation

- High reliability and repeatability