Kyubi System © is a business unit of Comercial Arqué S.A specialized in RFID technology.

T (34) 932 615 300

Email: info@kyubisystem.com

Kyubi System ©

Carretera del Mig, 54. Hospitalet de Llobregat, BARCELONA

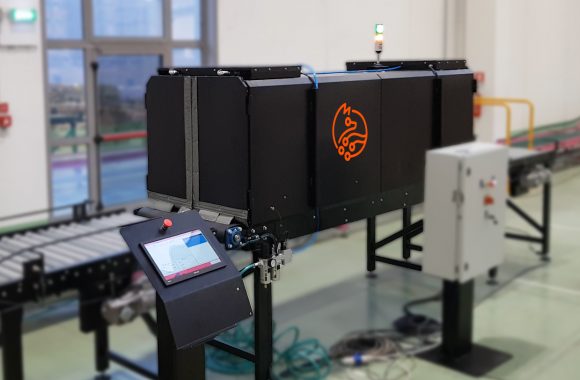

AIR! Tunnel RAIN RFID system has been specifically designed for high demanding production environments. Supported on Kyubi System’s AIR! proprietary technology at the service of precision and efficiency in mass readers, the AIR! Tunnel line offers unique RFID RAIN reading algorithms to achieve reliable massive reading+writing in the production line, aswell as a QA (quality control) tool.

The AIR! Tunnel’s product family has two versions: AIR! Tunnel for Boxes, for high speed massive reading+writing, and AIR! Tunnel for Pallets, for high demand reading+writing.

Its innovative “infinite opportunity” functionality offers the possibility of infinite second chance cycles, greatly increasing the accuracy against weak tag or difficulty to read+write, and drastically reduces investment in alternative return cycles.

AIR! Tunnel is an essential tool for RAIN RFID industrial environments. Robust and safe, it offers a high degree of automation and a wide variety of integration options, unique in the industry.

Designed to optimize logistic processes for high-volume retail, postal and parcel production lines, Air! Tunnel is able to run a Automatic Mode in which no human interaction is needed.

Air! Tunnel is perfect fit for highly-demanding logistic and production lines, and management of high volume warehouse flows or high speed QC processes.

Built in two versions, for holding packages or pallets, Air! Tunnel for Boxes achieves the highest precission-rate performance in the market while dispatching 12 boxes per minute and up to 1.200 tags per spin.

Meant to run in highly demanding environments, where accuracy and high success ratios matters, AIR! Tunnel for Pallets runs on an innovative and extremely precise RAIN RFID reading system with successful reading rates over 98%.

Interoperability is possible as AIR! Tunnel is able to be connected with any ERP and a wide variety of managing system softwares.

This feature double-checks the hardest-to-read batges, usually containing metallic or stacked items, through a smart second process of alternate readings. Infinite Opportunity feature will rewind the conveyor belt so it drags the box or pallet back into the tunnel, avoiding a secondary line for second runs.

TUNNEL

Designed to optimize logistic preocesses, high-end AIR! Tunnel device includes RFID tag devices that execute massive readings of items, packages and pallets with the highest precission rate of the market.

The AIR! Tunnel has been designed for Shipment Verification and Stock Management. Its “infinite opportunity” feature manages even the most hard-to-read badges through a smart process of alternate readings whilst syncing a smart back and forward movement of the package inside the tunnel.

Captured information is shown on the control screen, which is then can use to steer correctly their products. It is very productive in processes of goods receipt in warehouses, verification of exits to customers or recording of articles.

AIR! Tunnel

Standalone version for quality processes

Or integrated in industrial lines for production processesHigh speed mode for reading / writing

For unattended production environmentsLogical integration through REST API

With internal data model for real-time decision making3 different working modes

Manual, semi-manual and automatic"Infinite opportunity" cycle for error handling

No need for additional return conveyor belts

ADDITIONAL ACCESSORIES

FOR QUALITY CONTROL

EXTENDED GPIO

RFID HARDWARE

- AIR! Basic I4+2 (powered by IMPINJ)

- 3 external antennas.

- Touch PC screen with all AIM! software inside.

- All the necessary sensors for its correct operation.

- Motorized conveyor belt for <1000kg pallets.

- All RFID wiring needed.

APPLICATIONS

- Cargo expedition

- Picking and packing control

- Warehouse inventory

- Dinamic Recording

LATEST POSTS

VIEW ALL - 04 June 2025 by KYUBI, in RFID technology

04 June 2025 by KYUBI, in RFID technologyKYUBI SYSTEM | RFID Solutions: Leadership in Traceability and Automation Strengthens with TRAKARI

KYUBI SYSTEM | RFID Solutions consolidates its leadership in intelligent traceab...READ MORE + 13 May 2025 by KYUBI, in RFID technology

13 May 2025 by KYUBI, in RFID technologyRFID: The Definitive Guide for Business Leaders in 2025 – Unparalleled Efficiency and Traceability with Kyubi System

For you, visionary leader: The future of asset, inventory, and supply chain mana...READ MORE + 30 April 2025 by KYUBI, in RFID technology

30 April 2025 by KYUBI, in RFID technologyRFID: What It Is, How It Works and Why It Is the Key Technology for Business Optimisation in 2025 and Beyond

In the dynamic landscape of digitisation and Industry 4.0, RFID (Radio Frequency...READ MORE +